Online Store will close for orders on 18 December 2025. All orders will be dispatched 19 December. We shall be open and fully operational on Monday 5 January 2026.

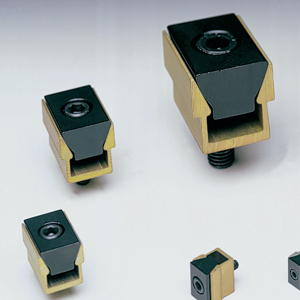

Uniforce Clamps

R1,672.00 – R4,373.00Price range: R1,672.00 through R4,373.00

Price Excludes VAT

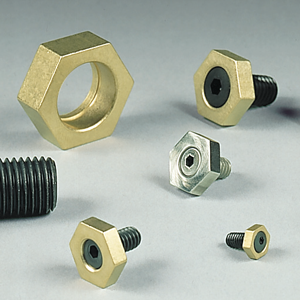

Uniforce Clamps consist of a steel wedge and 7075-T6 aluminium channel

Price below is per pack, quantity varies based on size, quantity shown in brackets

Backordered Mitee Bite items are delivered in 5 to 10 working days

For CAD models click HERE

The compact, economical MITEE-BITE Uniforce® Clamp enables you to fixture more parts on the machine table. The specially designed steel wedge spreads the clamping force uniformly on both sides of the 7075-T6 aluminum channel.

– Increases production.

– Minimizes tool changes.

– Holds two parts with equilateral clamping action.

– Ideal for clamping flat or round work pieces.

– Reduces wasted space.

– Easily mated to hydraulic pull cylinders.

– Ideal for pallet changers.

– Show with our Locating Rails

Metric

Part

No. |

Model |

|

A |

B |

B1 |

C |

D* |

E |

F† |

Thread

Size |

Maximum

Spread |

Max.

Torque

(N.m.) |

Holding

Force(N) |

No. of

Clamps

per pack |

Key

Size |

Replacement

Steel + Channel |

| 80250 |

250 |

|

6.1 |

6.9 |

6.4 |

8.1 |

5.3 |

3.6 |

6.4 |

M2 |

6.7 |

0.70 |

880 |

6 |

1.5 |

60305 |

60205 |

| 80375 |

375 |

|

9.1 |

9.7 |

9.5 |

11.9 |

7.9 |

4.7 |

9.5 |

M2.5 |

10.0 |

1.50 |

1350 |

6 |

2 |

60307 |

60207 |

| 80500 |

500 |

|

12.3 |

14.5 |

12.70 |

15.9 |

10.4 |

5.6 |

12.7 |

M4 |

13.2 |

3.40 |

2225 |

8 |

3 |

60310 |

60210 |

| 80750 |

750 |

|

18.6 |

19.0 |

19.05 |

23.8 |

16.1 |

9.5 |

19.0 |

M6 |

20.3 |

13.50 |

6675 |

6 |

5 |

60320 |

60220 |

| 81000 |

1000 |

|

24.8 |

25.9 |

25.40 |

31.7 |

20.8 |

12.7 |

25.4 |

M8 |

26.9 |

25.00 |

11125 |

4 |

6 |

60330 |

60230 |

| 81500 |

1500 |

|

37.3 |

38.6 |

38.10 |

47.6 |

30.8 |

19.0 |

38.1 |

M12 |

39.9 |

38.40 |

15575 |

2 |

10 |

60340 |

60240 |

| 82000 |

2000 |

|

49.7 |

51.5 |

50.80 |

63.5 |

41.2 |

25.4 |

50.8 |

M16 |

53.0 |

74.60 |

26700 |

2 |

14 |

60350 |

60245 |

|

D* – A milled slot wider than D dimension will insure clamp remains in line with workpiece. Clamp sides should not come in contact with slot walls during expansion.

F† The distance needed between workpieces for clamp clearance. Drill and tap mounting hole on the center of F dimension.